How to Effectively Improve the Quality of Feed by Improving the Production Process

In the process of feed production, three factors affect the quality: one is the quality of raw materials; the other is the feed formula; and the third is the production process, and these three influence each other. After controlling the quality of raw materials and feed formulations, how to improve the quality of feed by improving the production process has become an important means for many feed companies to improve product quality.

1. Feed moisture control

The issues that must be paid attention to in the feed production process are:

(1) How to improve the feed pellets quality;

(2) How to reduce dust;

(3) How to improve pellet feed-making machine production efficiency and reduce processing energy consumption;

(4) How to make full and effective use of steam, and cool enough to keep proper moisture in the feed.

2. Control of impurity removal of raw materials

A large number of impurities are mixed into feed ingredients. If they are not cleaned up in advance, it will affect product quality and even affect animal production performance, and loss of equipment during processing, and production.

It is generally believed that the impurity removal process of feed enterprises should pay attention to magnetic separation and screening equipment. While paying attention to the protection of the equipment, more attention should be paid to cleaning up the debris in the grain raw materials.

3. The crushing process of raw materials

The crushing of raw materials occupies an important position in feed processing, and at the same time has a significant impact on the performance of livestock and poultry production. The reduction of the material particle size increases the surface area of the feed and increases the chance of contact between the nutrients in the feed and digestive enzymes, thereby improving the utilization of nutrients in the feed. To meet the requirements of new crushing technology, crushing technology has gradually developed from primary crushing to secondary crushing and multiple crushing.

4. Mixing process

Mixing uniformity of materials is the guarantee of product quality, and the coefficient of variation (CV) of mixing uniformity is generally required to be less than 7%. Especially when adding a small or trace amount of additive raw materials, the uniformity of mixing is more important. The mixing effect of different mixing equipment has a great difference, which has a certain influence on animal growth. Therefore, it is important to understand whether the performance parameters are excellent when selecting poultry feed equipment.

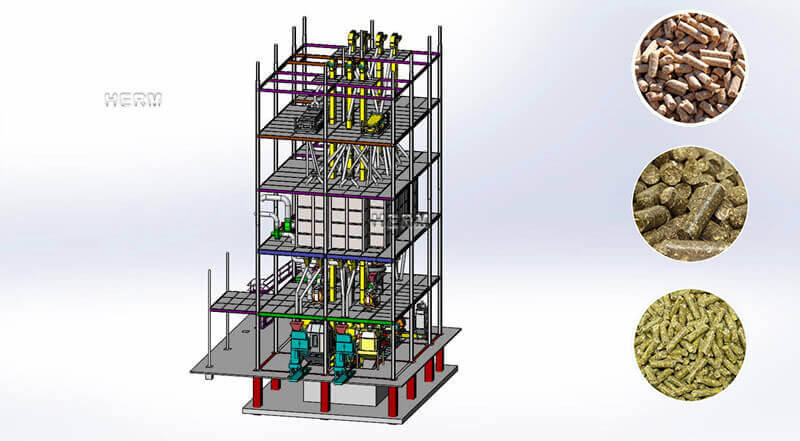

5. Pelleting process

In the process of compound feed processing, pelleting is an important link, which plays a role in linking the past and the next. This process is generally composed of three parts: pretreatment (magnetic separation, liquid addition, quenching, and tempering), granulation, and post-treatment (cooling, crushing, and classification). After the pelleting section, the material is transformed from powder to pellets. In this link, it is necessary to consider production efficiency without affecting product quality. It is necessary to ensure various physical indicators such as product particle hardness, powder content, water solubility, and material temperature after cooling.

(1) The powdery materials are cured. The conditioner greatly increases the gelatinization degree of the starch under the action of water and heat, and at the same time promotes the heat denaturation of the protein in the material, and the denatured protein is easy to enzymatically hydrolyzed, thereby improving the digestibility and utilization of the pellet feed

(2) Sterilize the powdery materials. The conditioner can condition the materials at a certain temperature to kill most of the pathogenic bacteria and ensure the hygiene level of the feed.

(3) Conditioning equipment can improve the pellet feed water resistance, in the process of quenching and tempered by through the role of the heat and water vapor, the sticky ingredients gelatinized starch, and modified protein in the raw material can give full play to the role of the binder, binding around other ingredients, under the extrusion of pressure molding roller, particle feed more close-grained, appearance is bright and clean, not easy to be in the process of feeding water erosion, The stability of feed particles in water is increased.

(4) The quenching and tempering equipment can improve the granulation of the material, increase the output, save the energy consumption of the granulation, and increase the life of the die and the pressure roller of the poultry feed pellet machine.

6. Summary

The production process is composed of the improvement of hardware equipment, advanced technology, and production management, not a simple combination, but more attention should be paid to the connection of details and the fine operation of key components. The equipment that does not conform to the feed production process, especially the old equipment, should be reformed and updated to improve the production process and feed quality.

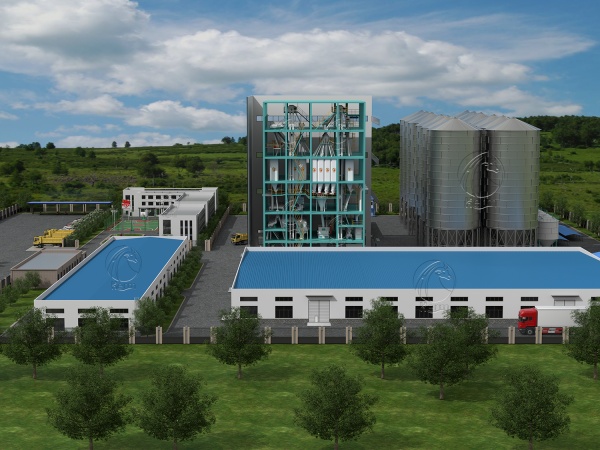

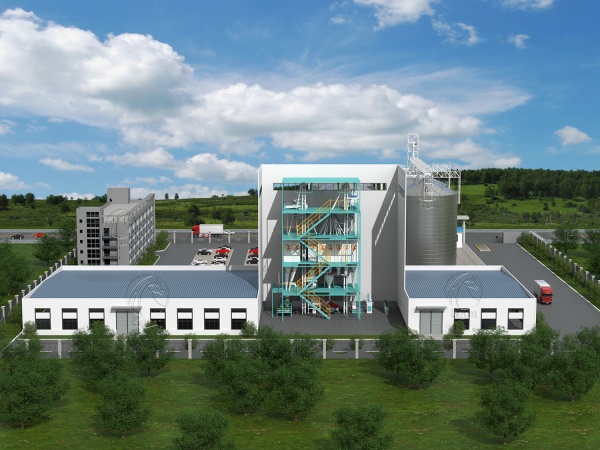

Henan Herm Machinery Co., Ltd was established in 2010 and has been devoted to the research and development of Feed Mill Machinery ever since. With more than 10 years of experience, Herm® has become a leading manufacturer and supplier of animal feed machines and complete animal feed production lines, cattle feed plants, poultry feed plants, animal feed pellet production lines, etc. It always endeavored to improve the quality of products and aims to meet the new requirements of the international market.

If You Are Ready to Start a Feed Pellet Plant Business, please contact us for the feed mill machine. We Can Provide Professional Design and Comprehensive Guidance According to Your Needs. Get in touch with us now!

Welcome Contact Us!

Henan Herm Machinery Co., Ltd

Email: info@hermmachinery.com

Whatsapp: 0086 18037508651