What is a Pellet Mill Machine?

What is a Pellet Mill Machine?

A pellet mill, also known as a feed pellet mill, is a vital machine in the feed processing industry. It transforms raw materials like corn, soybean meal, straw, grass, and rice husk into high-density pellets through crushing and pressing. This technology is widely employed across various sectors, including large, medium, and small aquaculture operations, grain and feed processing plants, livestock and poultry farms, and individual farmers.

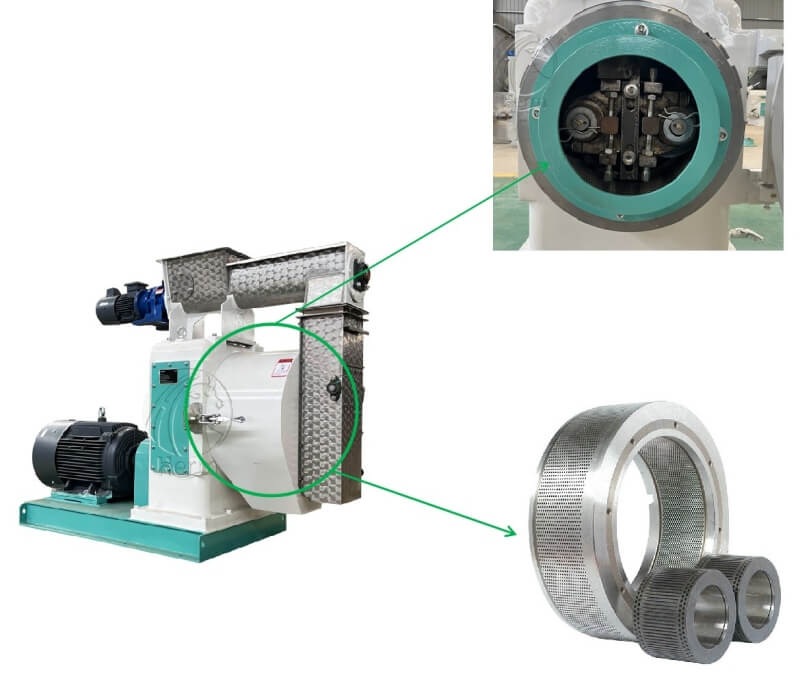

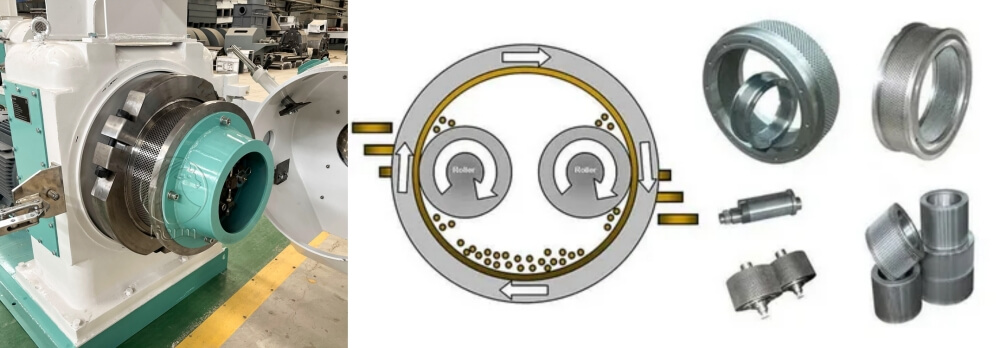

Pellet mills are primarily categorized into two types: ring die pellet machines and flat die pellet machines. While flat die machines are often used for home or small-scale operations—suitable for feeding chickens, ducks, rabbits, and cattle—ring die machines are designed for larger feed processing facilities.

Advantages of Ring Die Pellet Machines

High Production Capacity: Ring die pellet machines are engineered for higher throughput, making them ideal for large-scale operations. The unique ring die design allows for continuous production and efficient processing of bulk materials, resulting in significant time and labor savings.

Enhanced Pellet Quality: The ring die configuration promotes even distribution of pressure and heat during the pelleting process. This leads to a consistent pellet size and density, which is crucial for ensuring the nutritional quality of animal feed.

Versatility: These machines can handle a wide variety of raw materials, including those with varying moisture levels. Operators can adjust parameters easily to accommodate different feed formulations, enhancing flexibility in production.

Improved Energy Efficiency: With optimized steam conditioning, ring die machines utilize less energy per unit of output. This efficiency not only reduces operational costs but also contributes to a more sustainable production process.

Easy Adjustment and Maintenance: Ring die pellet machines feature external manual or electric cutters that allow operators to easily adjust pellet length according to specific requirements, whether for direct feeding or transportation purposes.

How to Operate a Ring Die Pellet Machine?

Preparation: Before starting the machine, inject gear oil and secure the oil injection hole. Check power lines to ensure safety and inspect belts and screws to confirm they are tight.

Steam Conditioning: The machine requires a boiler connection to regulate steam temperature, typically 105°C in and 75°C out. Proper steam contact is essential for optimal conditioning of the feed material.

Initial Setup: For first-time operators, pull the discharge handle to prevent material from entering the pressing chamber prematurely. Monitor steam conditions before commencing production.

Die and Roller Adjustment: Maintain a distance of 0.1 to 0.3 mm between the ring die and pressing roller to ensure an even material layer. This precision is vital for achieving high output and quality.

Running-in Process: New machines or molds should undergo a running-in period to remove any burrs that may affect performance. Properly ground molds ensure better granulation.

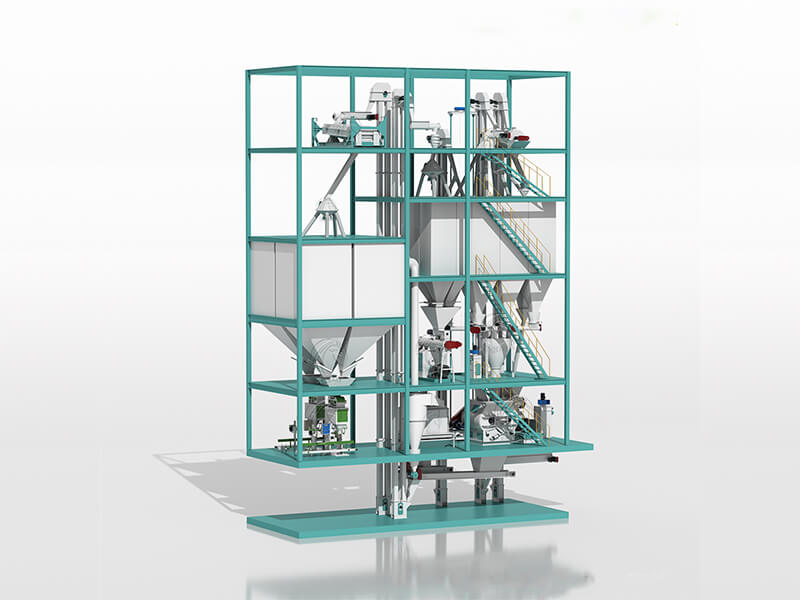

Production Workflow

Crushing Raw Materials: Begin by crushing the raw materials to a suitable particle size for efficient mixing and pelleting.

Mixing Ingredients: Blend various feed components, adding any necessary tracking additives to enhance nutritional value.

Pelleting Process: Feed the mixture into the ring die pellet machine for granulation. Monitor the process closely to ensure optimal conditions.

Cooling: Implement a cooler machine to quickly lower the temperature of the pellets post-production, preserving quality and preventing spoilage.

Packaging: Finally, a packing machine is utilized to efficiently package the pellets into bags of varying sizes (5kg, 25kg, 50kg) based on market demand. Manual and automatic packaging options allow flexibility depending on budget and scale.

In conclusion, the ring die pellet mill stands out as a highly efficient and versatile solution for modern feed production. By investing in this technology, businesses can enhance productivity, ensure feed quality, and adapt to the evolving needs of the agricultural sector.

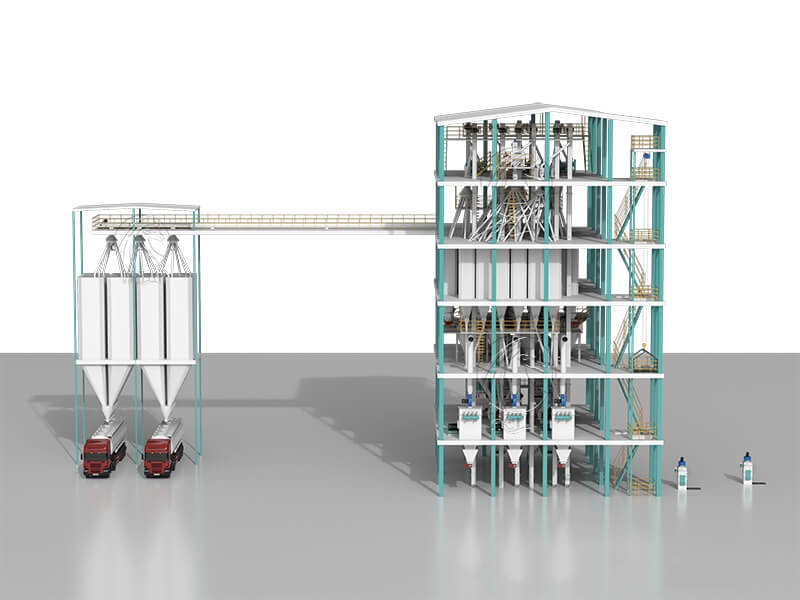

Applications of Ring Die Pellet Machines in Pellet Production Lines

Ring die pellet machines play a crucial role in integrated pellet production lines, contributing to a streamlined and efficient manufacturing process. Here are key applications within a pellet production line:

Seamless Integration: Ring die pellet machines can be easily integrated into existing production lines, allowing for smooth transitions between crushing, mixing, pelleting, and cooling stages. This integration minimizes downtime and enhances overall workflow efficiency.

Continuous Production: The design of ring die pellet machines supports continuous operation, enabling producers to maintain high output levels without frequent interruptions. This capability is vital for meeting large-scale demand while maintaining quality.

Optimized Material Handling: In a complete production line, materials are transported automatically between each stage, from the crusher to the mixer, and finally to the pellet mill. This automation reduces manual labor and the risk of contamination.

Enhanced Quality Control: The ability to monitor and adjust parameters in real-time ensures consistent pellet quality. With integrated sensors and controls, operators can optimize steam conditioning and pellet density during production.

Post-Pelleting Solutions: After pelleting, ring die machines can be paired with cooling systems to quickly reduce pellet temperature and moisture, preserving nutritional value. Additionally, they can connect to automated packing systems for efficient bagging and storage.

Scalability: As demand increases, producers can easily scale up production by adding more ring die pellet machines to the existing line, ensuring flexibility to meet varying market needs without significant redesigns.

In summary, the inclusion of ring die pellet machines in pellet production lines not only enhances productivity and efficiency but also ensures high-quality feed that meets the demands of modern agriculture.

Henan Herm Machinery Co., Ltd was established in 2010 and has been devoted to the research and development of Feed Mill Machinery ever since. With more than 10 years of experience, Herm® has become a leading manufacturer and supplier of animal feed machines and complete animal feed production lines, cattle feed plants, poultry feed plants, animal feed pellet production lines, etc. It always endeavored to improve the quality of products and aims to meet the new requirements of the international market.

If You Are Ready to Start a Feed Pellet Plant Business, please contact us for the feed mill machine. We Can Provide Professional Design and Comprehensive Guidance According to Your Needs. Get in touch with us now!

Welcome Contact Us!

Henan Herm Machinery Co., Ltd

Email: info@hermmachinery.com

Whatsapp: 0086 18037508651