Henan HERM Machinery 3-4T Feed Production Line Boosts Efficiency in Kenya

Henan HERM Machinery Provides 3-4T Feed Production Line to Boost Chicken and Cattle Feed Production Efficiency for Kenyan Client

Henan HERM Machinery has recently supplied a 3-4T feed production line to a client in Kenya, significantly enhancing the production efficiency of chicken and cattle feed. This project not only demonstrates Henan HERM Machinery's advanced technology in feed processing equipment but also highlights the company's strong capability in offering "one-stop feed processing solutions." With tailored design solutions and comprehensive services, the Kenyan client has seen a notable improvement in production efficiency and product quality.

Client Background and Needs:

The Kenyan client primarily produces chicken and cattle feed and faced challenges in improving production efficiency, reducing production costs, and adapting to varying feed production needs. To meet diverse market demands and ensure feed quality, the client required a flexible production line that could produce both pellet and powder feed, with the ability to adjust formulas and equipment configuration based on requirements. Additionally, the client needed the production line to fit within their existing facility layout, allowing for future expansion and maintenance.

Henan HERM Machinery Solution:

To meet the Kenyan client’s needs, Henan HERM Machinery designed a high-efficiency, flexible 3-4T feed production line. This production line encompasses processes including crushing, mixing, oil addition, pelletizing, cooling, grinding, sieving, and packaging, and offers different mold sizes for various animal feed requirements. By changing the molds and formulas, the client can easily produce multiple types of feed, including chicken and cattle feed.

Key Equipment Configuration:

Water Drop Hammer Mill:

Featuring a highly efficient water-drop design, equipped with a Siemens motor and infinitely variable speed feeder, this machine effectively improves crushing efficiency and ensures uniform particle size. It also reduces energy consumption, balancing low power usage with high output. The design minimizes noise and dust, improving the working environment.

Double Shaft Paddle Mixer:

This machine can efficiently mix materials within 90 seconds and ensures an even distribution of feed ingredients. Its double-shaft paddle design ensures the uniform mixing of high-viscosity raw materials and powder, significantly improving feed quality and utilization.

Precise Oil Additive Injector:

Featuring an automated control system, this device accurately adjusts the oil addition, ensuring even distribution of oils and enhancing the feed's nutritional value, flavor, and digestibility.

Pellet Mill (with Adjustable Molds):

Equipped with multiple mold sizes, users can quickly adjust molds to meet the requirements of different feed types. The pellet mill operates with high efficiency and stability, ensuring the smooth production of pellet feed and enhancing the market competitiveness of the final product.

Feed Cooler:

The high-efficiency cooler quickly lowers the temperature of the pellet feed, maintaining the feed’s hardness and quality. This cooling process not only lowers the feed’s temperature but also prevents spoilage from excessive heat, ensuring long-term preservation.

Roller Crusher:

Specially added as per the client’s request, this device is primarily used for producing chick feed, further crushing pellets into smaller sizes, ensuring better digestibility for young chicks. The high-performance roller crusher significantly enhances chick feed production efficiency.

Vibrating Screener and Packaging Machine:

The vibrating screener effectively removes substandard pellets, ensuring consistent feed quality. The packaging machine automatically packages feed in various sizes, meeting market demands.

Design Highlights and Optimizations:

Flexible Production Mode:

By changing molds and adjusting formulas, the production line can flexibly switch between different types of feed, catering to diverse customer needs. The client can produce both standard pellet feed and powder feed, meeting the nutritional requirements of different animals.

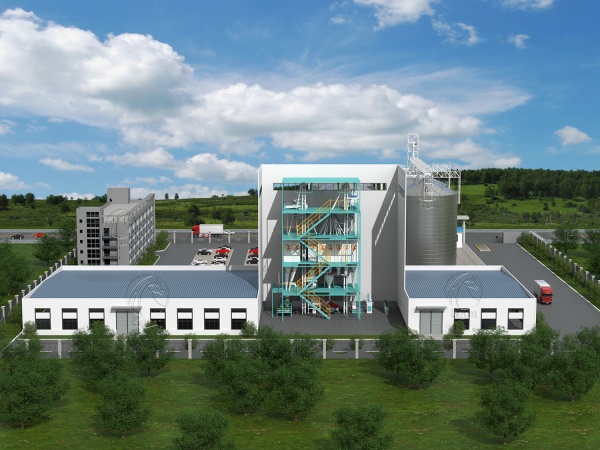

Optimized Factory Layout:

Henan HERM Machinery provided a customized factory layout based on the client’s existing space and structure. Through precise measurements and rational planning, we ensured that the equipment's installation locations maximized the available space, enhancing production efficiency and leaving room for future equipment expansion.

Modular Design:

All equipment is designed with a modular approach, allowing the client to adjust and replace parts as needed, facilitating future upgrades and expansions. Standardization and modularization give the client the flexibility to add or remove equipment based on changing production needs.

Simplified Operation and Maintenance:

The equipment operation process is streamlined and equipped with a modern PLC control system, reducing manual intervention and increasing automation. Furthermore, the production line design takes future maintenance needs into account, providing adequate maintenance space to minimize downtime and reduce maintenance costs.

Henan HERM Machinery’s One-Stop Service Advantage:

Henan HERM Machinery offers not only high-quality equipment but also a full range of "one-stop services," assisting clients throughout the entire process—from project initiation to production line commissioning and equipment maintenance. This comprehensive support helps clients achieve high efficiency and convenience.

Needs Analysis and Tailored Solutions:

At the project’s outset, our technical team works closely with the client to conduct an in-depth analysis of their production needs, factory space, and future development plans. Based on this information, we design the most suitable equipment and production line configuration.

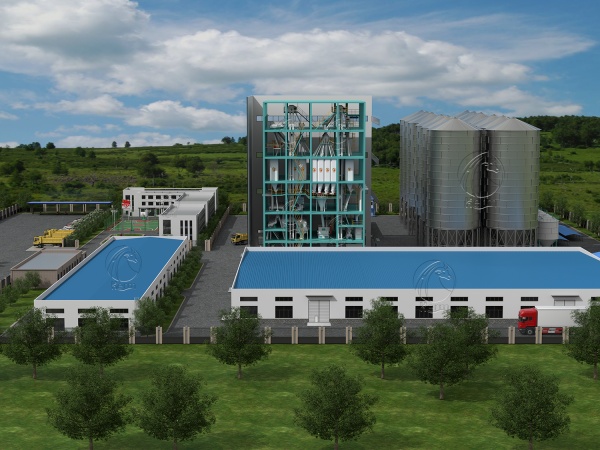

Detailed 3D Design and Layout Planning:

Henan HERM Machinery provides detailed 3D design drawings, helping clients visualize the layout and operation of each stage of the production process. Additionally, our design team delivers the entire factory’s layout renderings, ensuring the smooth and efficient operation of the production line.

Project Management and Seamless Installation and Commissioning:

Henan HERM Machinery offers comprehensive project management services, including equipment transportation, installation, and commissioning, ensuring timely and high-quality project completion. Our engineering team assists with installation and commissioning on-site and provides thorough training for the client’s operators to ensure they are proficient in operating and maintaining the equipment.

After-Sales Service and Long-Term Technical Support:

After installation, Henan HERM Machinery’s after-sales service team provides ongoing technical support and maintenance. Whether it's troubleshooting, line optimization, or equipment upgrades, we offer prompt and effective solutions to ensure the long-term stability and performance of the production line.

Client Feedback:

The Kenyan client highly praised Henan HERM Machinery’s "one-stop service," particularly the full support provided in equipment selection, factory layout design, and ongoing technical assistance. They reported that after the production line was commissioned, feed production efficiency increased significantly, production costs were reduced, and product quality improved. The client was very satisfied with our professionalism and service and plans to continue collaborating with us on future projects.

Henan HERM Machinery’s Advantage:

Through this collaboration, Henan HERM Machinery once again demonstrated its leadership in the feed processing system industry. With years of professional experience, we provide tailored, one-stop services—from equipment design, factory layout, installation, and commissioning to after-sales support—fully meeting client needs. We are committed to providing efficient, stable, and energy-saving solutions that help clients stand out in a competitive market.

Contact Us:

If you need a high-efficiency and flexible feed production line or wish to enhance your existing production line, Henan HERM Machinery is your ideal choice. We offer customized solutions for every client, ensuring you get the best return on investment. Contact our sales and technical teams for more project consultations and solutions. Henan HERM Machinery—our "one-stop service" ensures your production is more efficient, stable, and supports your business's successful development!

Henan Herm Machinery Co., Ltd was established in 2010 and has been devoted to the research and development of Feed Mill Machinery ever since. With more than 10 years of experience, Herm® has become a leading manufacturer and supplier of animal feed machines and complete animal feed production lines, cattle feed plants, poultry feed plants, animal feed pellet production lines, etc. It always endeavored to improve the quality of products and aims to meet the new requirements of the international market.

If You Are Ready to Start a Feed Pellet Plant Business, please contact us for the feed mill machine. We Can Provide Professional Design and Comprehensive Guidance According to Your Needs. Get in touch with us now!

Welcome Contact Us!

Henan Herm Machinery Co., Ltd

Email: info@hermmachinery.com

Whatsapp: 0086 18037508651