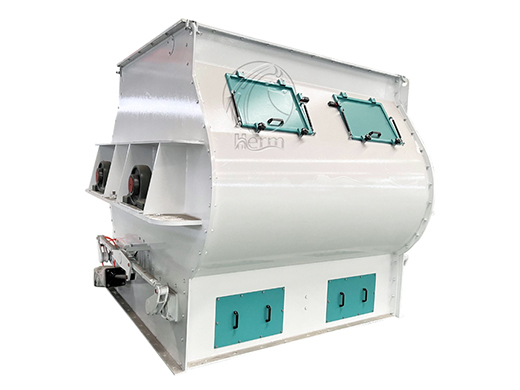

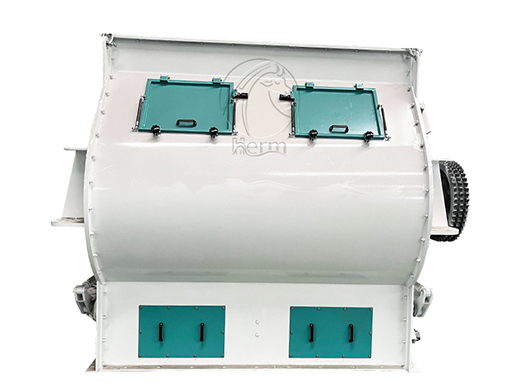

SLHS Shaft Paddle Mixer

- Capacity: 500-2000 kg/batch

- Feed Pellet Size: custom

- Feed Pellet Forming Rate: ≥95

- Application: poultry, livestock, ruminant,cattle, sheep, pig, goat, fish, shrimp, crab, aquatic, etc

Herm Machinery's latest double shaft paddle mixer offers numerous benefits, ensuring gentle handling, low energy consumption, high capacity, minimal space requirements, and flexible filling for feed mixers.